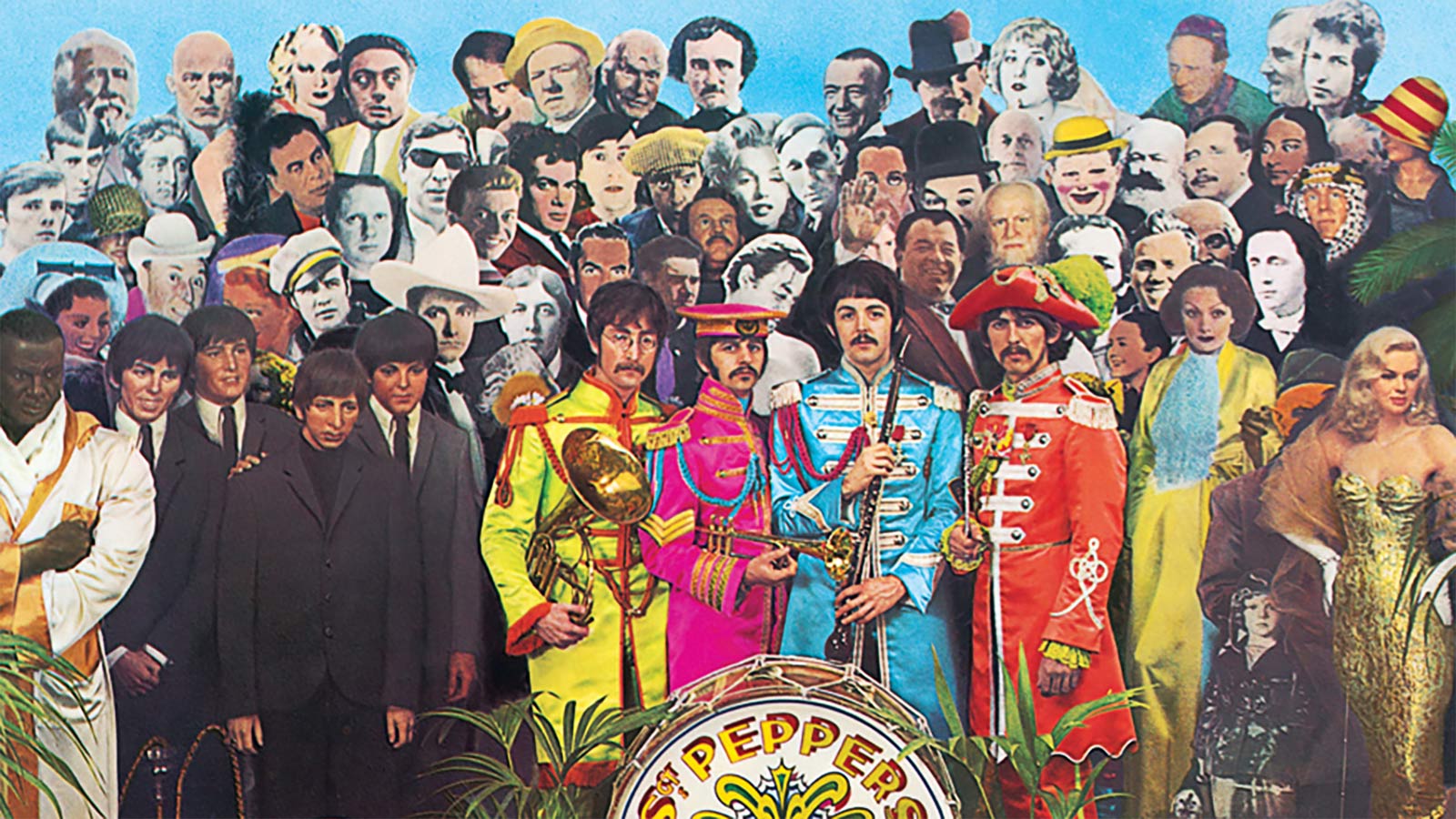

It was seventy years ago today, that Sgt. Pepper taught the band to play, And twenty-five years ago, that Coastal Climate Control made a show.

And then, three years later in 1995, in the midst of a major snow storm in Annapolis, with skiers and snowmobiles having fun on the streets, Coastal entered the digital age. A computer was purchased, Quickbooks installed, and the next few snowy days were spent entering customer details and setting up the system. The old ledger book was re-purposed to prop up the TV, and Coastal was ready to start the Spring armed with new technology and a floppy disk full of digital dreams.

Some of the boatyards and marinas were not too enthusiastic about getting into computers back then, and there was much concern about loss of jobs. For the next few years I often encountered fully analog offices where pen and paper still ruled supreme, but of course that all gradually changed. It’s hard now to imagine how it was in those offices back then, often seen through a haze of cigarette smoke, but inevitably progress prevailed. I don’t recall any tales of mass job losses, protests, etc., so I guess it all transitioned fairly smoothly. In the early days, the computer was mainly used as an office administration tool, but then along came the internet and all that goes with it. Now we are all immersed in technology up to our data limits. What an incredible leap in technology in what seems such a short span of time.

What hasn’t changed in 25 years is the need for a trained professional to come to the aid of a customer with a problem, whether in person or at the end of a phone or Ethernet cable. What has changed, however, is that nowadays many customers empower themselves with boat loads of information gained from internet searches which leads them to the conclusion that they don’t require a technician’s visit, as all they need is a bit of on-line help.

We’re living in a DIY world with the internet and answers close at hand. When your boat’s refrigeration isn’t working correctly, how many of you go to the internet, forums, manufacturer’s web site to find solutions? We’ve all learned, too often the hard way, that not all web pages are trustworthy sources of information; some information should be taken with a grain of salt; others with a truck load.

We’re living in a DIY world with the internet and answers close at hand. When your boat’s refrigeration isn’t working correctly, how many of you go to the internet, forums, manufacturer’s web site to find solutions? We’ve all learned, too often the hard way, that not all web pages are trustworthy sources of information; some information should be taken with a grain of salt; others with a truck load.

It’s starting to get crazy again on our help line, like it seems to every year about this time. I guess that there’s a big increase in numbers of boats swanning around down south now that it’s holiday season and it’s getting nippy up north. Lucky them!

It’s starting to get crazy again on our help line, like it seems to every year about this time. I guess that there’s a big increase in numbers of boats swanning around down south now that it’s holiday season and it’s getting nippy up north. Lucky them! There is much talk and discussion in certain forums about how to determine the correct refrigerant charge level for a capillary tube refrigeration system, but there is only one, simple method that will result in the perfect charge in a Frigoboat system; the frost-line method. Pressures and current draw can be monitored to confirm that these are within expected limits, but there is no better way to guage the refrigerant level than with the frost-line method.

There is much talk and discussion in certain forums about how to determine the correct refrigerant charge level for a capillary tube refrigeration system, but there is only one, simple method that will result in the perfect charge in a Frigoboat system; the frost-line method. Pressures and current draw can be monitored to confirm that these are within expected limits, but there is no better way to guage the refrigerant level than with the frost-line method.

I recently had an air conditioning system replaced at my house. Out went the old energy hog with a noisy, fixed speed compressor, and in came a high efficiency unit with a quiet compressor and fan, both of which run at variable speeds. So, today’s question is: Why does varying the compressor speed increase efficiency, and how is that achieved?

I recently had an air conditioning system replaced at my house. Out went the old energy hog with a noisy, fixed speed compressor, and in came a high efficiency unit with a quiet compressor and fan, both of which run at variable speeds. So, today’s question is: Why does varying the compressor speed increase efficiency, and how is that achieved? Efficiency in refrigeration and air conditioning systems is measured as a ratio of power out to power in, and can be in several forms. The Energy Efficiency Ratio (EER) is the ratio of output cooling energy in Btu’s to input electrical energy in watts under certain fixed conditions. So a system with an EER rating of 10 will produce 10 Btu’s of cooling for every watt of power consumed under the specified conditions. The Seasonal Energy Efficiency Ratio (SEER) that is used in commercial and residential equipment is similar to the EER, but is assessed over time and under varying conditions.

Efficiency in refrigeration and air conditioning systems is measured as a ratio of power out to power in, and can be in several forms. The Energy Efficiency Ratio (EER) is the ratio of output cooling energy in Btu’s to input electrical energy in watts under certain fixed conditions. So a system with an EER rating of 10 will produce 10 Btu’s of cooling for every watt of power consumed under the specified conditions. The Seasonal Energy Efficiency Ratio (SEER) that is used in commercial and residential equipment is similar to the EER, but is assessed over time and under varying conditions. Unless other actions are also taken, using a vacuum pump to evacuate a R134a refrigeration system will almost certainly not result in a permanent resolution to particle or moisture blockages. This is true no matter how deep the vacuum or for how long the vacuum pump is run.

Unless other actions are also taken, using a vacuum pump to evacuate a R134a refrigeration system will almost certainly not result in a permanent resolution to particle or moisture blockages. This is true no matter how deep the vacuum or for how long the vacuum pump is run. Recently, a customer contacted us for some troubleshooting advice. He said that his refrigeration system was not working and the compressor not running. Apparently he had a technician look at the system who reported that he checked the refrigerant level and said it was OK.

Recently, a customer contacted us for some troubleshooting advice. He said that his refrigeration system was not working and the compressor not running. Apparently he had a technician look at the system who reported that he checked the refrigerant level and said it was OK.

Here's a fact: Heat travels in one direction only; from warm to cold. So if a temperature difference exists between two items, the warmer item will lose heat to the cooler item; so the warmer item gets colder, the colder item gets warmer.

Here's a fact: Heat travels in one direction only; from warm to cold. So if a temperature difference exists between two items, the warmer item will lose heat to the cooler item; so the warmer item gets colder, the colder item gets warmer. It's happened again, and I'm getting really tired of it. Yet another call from a boat owner who called in what he thought was a trained and experienced marine refrigeration technician to fix a poorly performing system, and now it's working worse than it was before! Why? Because the technician had added refrigerant, or "put in a shot of Freon" to what previously was a perfectly charged system.

It's happened again, and I'm getting really tired of it. Yet another call from a boat owner who called in what he thought was a trained and experienced marine refrigeration technician to fix a poorly performing system, and now it's working worse than it was before! Why? Because the technician had added refrigerant, or "put in a shot of Freon" to what previously was a perfectly charged system.

Our “collection” of these expensive, heavy, and cumbersome hunks of stainless steel is now destined for the scrap pile. This long overdue but necessary move will free up valuable warehouse space for more of the aluminum flat-plate evaporators that have all but replaced the holding plate.

Our “collection” of these expensive, heavy, and cumbersome hunks of stainless steel is now destined for the scrap pile. This long overdue but necessary move will free up valuable warehouse space for more of the aluminum flat-plate evaporators that have all but replaced the holding plate.