Phone: (301) 352-5738

Email: info@CoastalClimateControl.com

Office | Warehouse:

1598 Whitehall Road, Suite D

Annapolis, Maryland 21409

Variable Speed Refrigeration and Air Conditioning Compressors

I recently had an air conditioning system replaced at my house. Out went the old energy hog with a noisy, fixed speed compressor, and in came a high efficiency unit with a quiet compressor and fan, both of which run at variable speeds. So, today’s question is: Why does varying the compressor speed increase efficiency, and how is that achieved?

I recently had an air conditioning system replaced at my house. Out went the old energy hog with a noisy, fixed speed compressor, and in came a high efficiency unit with a quiet compressor and fan, both of which run at variable speeds. So, today’s question is: Why does varying the compressor speed increase efficiency, and how is that achieved?

Golden Rule: The longer and slower a compressor can run, the more efficient it will be Efficiency in refrigeration and air conditioning systems is measured as a ratio of power out to power in, and can be in several forms. The Energy Efficiency Ratio (EER) is the ratio of output cooling energy in Btu’s to input electrical energy in watts under certain fixed conditions. So a system with an EER rating of 10 will produce 10 Btu’s of cooling for every watt of power consumed under the specified conditions. The Seasonal Energy Efficiency Ratio (SEER) that is used in commercial and residential equipment is similar to the EER, but is assessed over time and under varying conditions.

Efficiency in refrigeration and air conditioning systems is measured as a ratio of power out to power in, and can be in several forms. The Energy Efficiency Ratio (EER) is the ratio of output cooling energy in Btu’s to input electrical energy in watts under certain fixed conditions. So a system with an EER rating of 10 will produce 10 Btu’s of cooling for every watt of power consumed under the specified conditions. The Seasonal Energy Efficiency Ratio (SEER) that is used in commercial and residential equipment is similar to the EER, but is assessed over time and under varying conditions.

When a fixed speed compressor is operating under light-load conditions, i.e. nighttime, cool weather, etc., a fixed-speed compressor will be running for short spurts and do a lot of cooling in a hurry, which is inherently very inefficient. If we were to be able to slow the compressor down during periods of light load, the system would run longer and be more efficient overall, but would still have the required capacity available for high heat-load conditions.

A good illustration of this phenomenon can be found in the specifications for the marvelous variable-speed refrigeration compressors we use from Secop (formally Danfoss) in our Frigoboat refrigeration systems. The following table shows the EER of the Secop BD50 compressor at various speeds in a typical refrigeration application.

|

Compressor speed |

Compressor EER |

|

2,000 RPM |

5.15 |

|

2,500 RPM |

4.88 |

|

3,000 RPM |

4.88 |

|

3,500 RPM |

4.85 |

In the example above, we will get 0.3 more Btu’s of cooling for every watt of electrical energy consumed if we can run the compressor at the slowest speed when possible, and not always at the maximum. In a typical application that would result in around 25 more Btu’s of cooling per hour simply by running this compressor longer and slower, and that is exactly what Frigoboat’s Merlin II Smart Speed Controller does, gaining around a 15% increase in efficiency in the process.

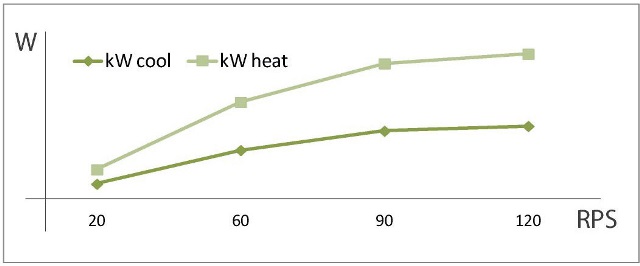

Variable speed compressors are now available in the smaller (up to 60,000Btu) chilled-water air conditioning units from Climma. As well as the obvious efficiency benefits, we now have compressors that:

Variable speed compressors are now available in the smaller (up to 60,000Btu) chilled-water air conditioning units from Climma. As well as the obvious efficiency benefits, we now have compressors that:

1) have absolutely zero starting surge (sorry, all you generator salesmen out there)

2) that are truly world-power compatible by being able to operate on both 50Hz and 60Hz; and

3) that can be set at a low capacity limit for use on small generators, inverters, or inadequate dock power.

These amazing machines are already transforming how we approach air conditioning on mid-sized vessels, and are proving to be especially attractive for catamaran installations.

Compressor Speed Control Basics

Hermetic refrigeration and air conditioning compressors comprise of an electric motor and a compression device inside a sealed housing. One way to vary the speed of an electric motor is to make it operate from Direct Current (DC) and then vary the operating voltage.

But that would be impractical for many reasons, the least of which would be the need to employ a commutator and brushes, as a permanent magnet motor’s speed cannot be varied. This dictates that the motor must be powered by Alternating Current (AC), as is already common, but to somehow be able to vary the speed. Standard AC powered compressors operate at a speed that is synchronous to the frequency, or Hertz (Hz), of the power supply. A typical motor running on 60Hz American power will spin at close to 3,600 RPM, whereas the same motor operating on the same voltage but on 50 Hz European/rest-of-the-world power will run slower, at around 3,000 RPM.

Standard AC powered compressors operate at a speed that is synchronous to the frequency, or Hertz (Hz), of the power supply. A typical motor running on 60Hz American power will spin at close to 3,600 RPM, whereas the same motor operating on the same voltage but on 50 Hz European/rest-of-the-world power will run slower, at around 3,000 RPM.

For a well-traveled vessel this presents a conundrum, because while this variation in speed from different power supplies may not be problematic for many types of application, i.e. fans and pumps, it can cause big problems in refrigeration and air conditioning compressors, where lubrication, overheating, and other issues can initiate compressor failure. Single-phase air conditioning and refrigeration compressors are designed to operate safely only on either 50Hz or 60Hz power, but not both.

There is one way we can safely operate a standard compressor within a limited range of speeds, and that is with a compressor built to operate from three-phase power. This is common practice with the large compressors used in Climma’s chillers for super-yachts, where they can be safely operated between about 2,500 RPM and 4,000 RPM and ramp up slowly from 0 RPM at start-up to eliminate starting surge.

It’s amazing to note that we have this same clever technology in the small variable-speed refrigeration compressors mentioned earlier.

So now that we know the secret of the hardware, i.e. three-phase/three-winding compressor motors, it’s time to unlock the mysteries of the electronics that drive them, and let’s start with those small Secop DC powered refrigeration compressors. These have three identical compressor windings, and the associated electronic controller takes the 12v or 24v DC input and pulses it out to each winding in turn at varying rates to turn the shaft and give varying compressor speeds; it’s basically a variable-frequency inverter powering a three-phase motor. The frequency, and hence compressor speed, is dictated by the value of resistance in the thermostat circuit, and the clever Merlin II Smart Speed Controller varies this resistance dependent on thermostat opening times and other criteria.

On the other end of the scale, in our large super-yacht chiller compressors, we have AC power supplies that may be either single-phase or three-phase, and which will need to be converted somehow into a variable-frequency three-phase supply for the three-phase compressor. To achieve this, the incoming AC power is first converted to high voltage DC, typically 300v to 600v, which is then inverted back to three-phase, variable-frequency AC. These controllers are often referred to as frequency drives or inverters, and provide for limited-range variable speed and zero start-up surge.

And that leads us to the ultimate solution, which is a truly variable-speed compressor operating over a wide range of speeds resulting in large variations in system capacity. To achieve this, a multitude of sensors and electronic controls must be incorporated into a system using a purpose-built compressor and sophisticated electronics.The same process of converting the incoming AC to DC and then inverting it back to AC is employed, similar to that in the limited frequency-range systems, but now we are able to run the compressor safely anywhere between 600 RPM and 6,000 RPM.

And that leads us to the ultimate solution, which is a truly variable-speed compressor operating over a wide range of speeds resulting in large variations in system capacity. To achieve this, a multitude of sensors and electronic controls must be incorporated into a system using a purpose-built compressor and sophisticated electronics.The same process of converting the incoming AC to DC and then inverting it back to AC is employed, similar to that in the limited frequency-range systems, but now we are able to run the compressor safely anywhere between 600 RPM and 6,000 RPM.

The electronics packages on these systems can produce a considerable amount of heat when they’re working hard, and so require some sort of cooling device. The standard method of electronics cooling is by a large fan, which is required to move a large volume of air in order to be effective in a hot environment like an engine room.

By contrast, the Climma DC50 and DC65 variable-speed chillers incorporate water cooling of the electronics by using some of the chiller systems’ circulating water, and this feature is already standard on the Climma super-yacht chillers. Water cooling of the electronics reduces power consumption by keeping electronic temperatures low while eliminating the need for a cooling fan, and not having a fan means not circulating salt-laden air over the electronics.

By accepting you will be accessing a service provided by a third-party external to https://coastalclimatecontrol.com/